Lately, I’ve been trying to find out more about what happens with our trash - I toured the Ada County Landfill a while back, and this week, I’m talking about a tour of an interesting place that works on “What you can do with random plastics?” from the Boise Orange Bag program (whatever they happen to be calling it this week). Scott Phillips is a local professor with a very interesting little “plastics research lab” buried in a small industrial building, and he’s been working on what, exactly, you can do with the random mixed plastics coming out of the waste stream in Boise.

Art Results

One of the major things Scott has been doing with the plastic waste is creating “modern art” - but out of reused plastics. All of the pieces here - both epoxied and polished, or raw - are created with plastic coming out of the waste stream in various forms. The results are certainly interesting!

This is a large piece with about an inch of epoxy on top of it, though the plastic debris is at various depths in it.

Another large piece resembles water and ice floes - but it’s entirely waste plastic and a layer of epoxy!

Most of the “black and white” pieces he produces are made out of waste lumber wrap - the plastic tarp that wraps the bricks that dimensional lumber ships in. They’re a plastic tarp weave and hard to process, but twisting them and applying heat and pressure turns them into some interesting patterns.

Add epoxy and some higher contrast material, and you get something like this out of the lumber overwrap.

Frame the stuff, give it a coat of epoxy, and you’ve got either interesting coasters, or something that could be hung on a wall. Again, all of this is recycled plastic!

Grinding it Down

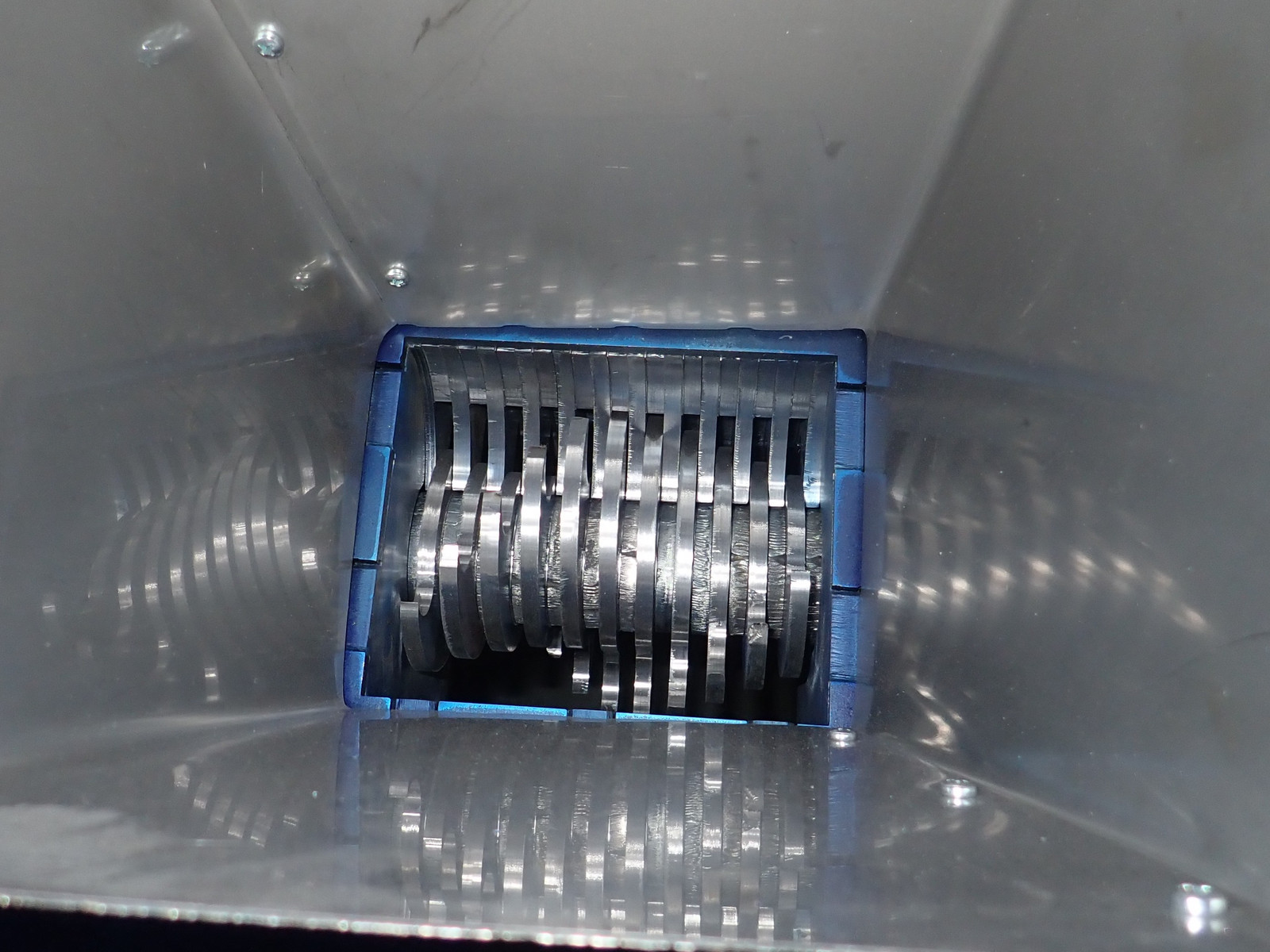

Most of the techniques being developed here start with taking bulk mixed plastic and turning it into very tiny chunks. A bunch of sharp steel cutter wheels do this job quite well - and, in line with the R&D focused nature of this lab, they make their own cutters out of hardened steel plates. This allows quite a bit of experimentation with what works best for the random mixes of plastic they’re dealing with. You can see a range of cutter wheels and spacers that go between them punched out of this sheet.

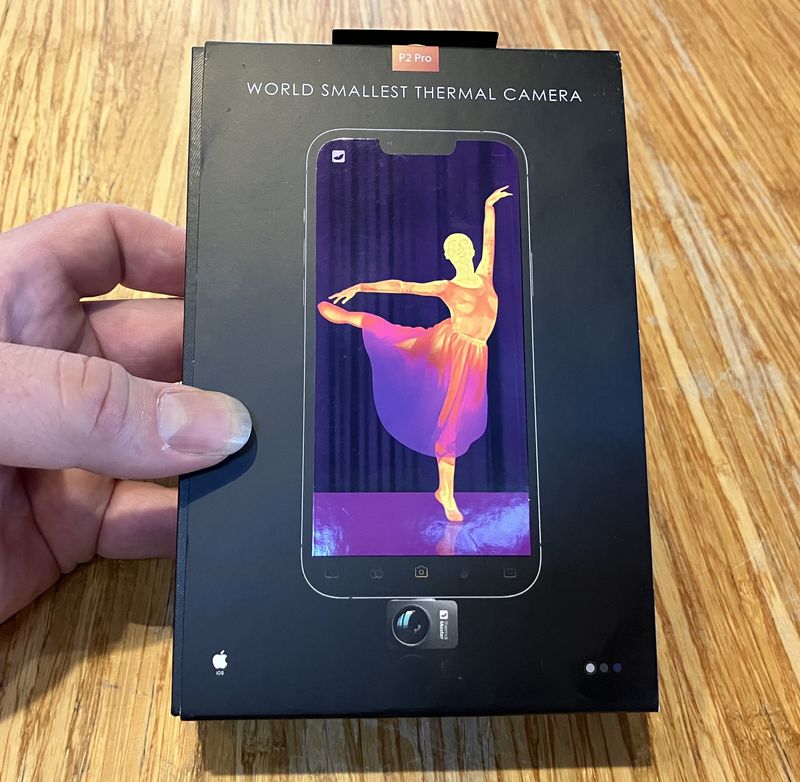

And in a capability sure to make some friends of mine jealous, they have their own laser cutter that can handle some properly stout materials… and, as always, “Caution: Do not look into laser with remaining eye.”

These pieces get assembled into the business end of various grinders. It’s literally just stacks of cut steel, in various shapes, some fixed, and some on a central shaft that spins with all the torque and turns large material into very tiny pieces.

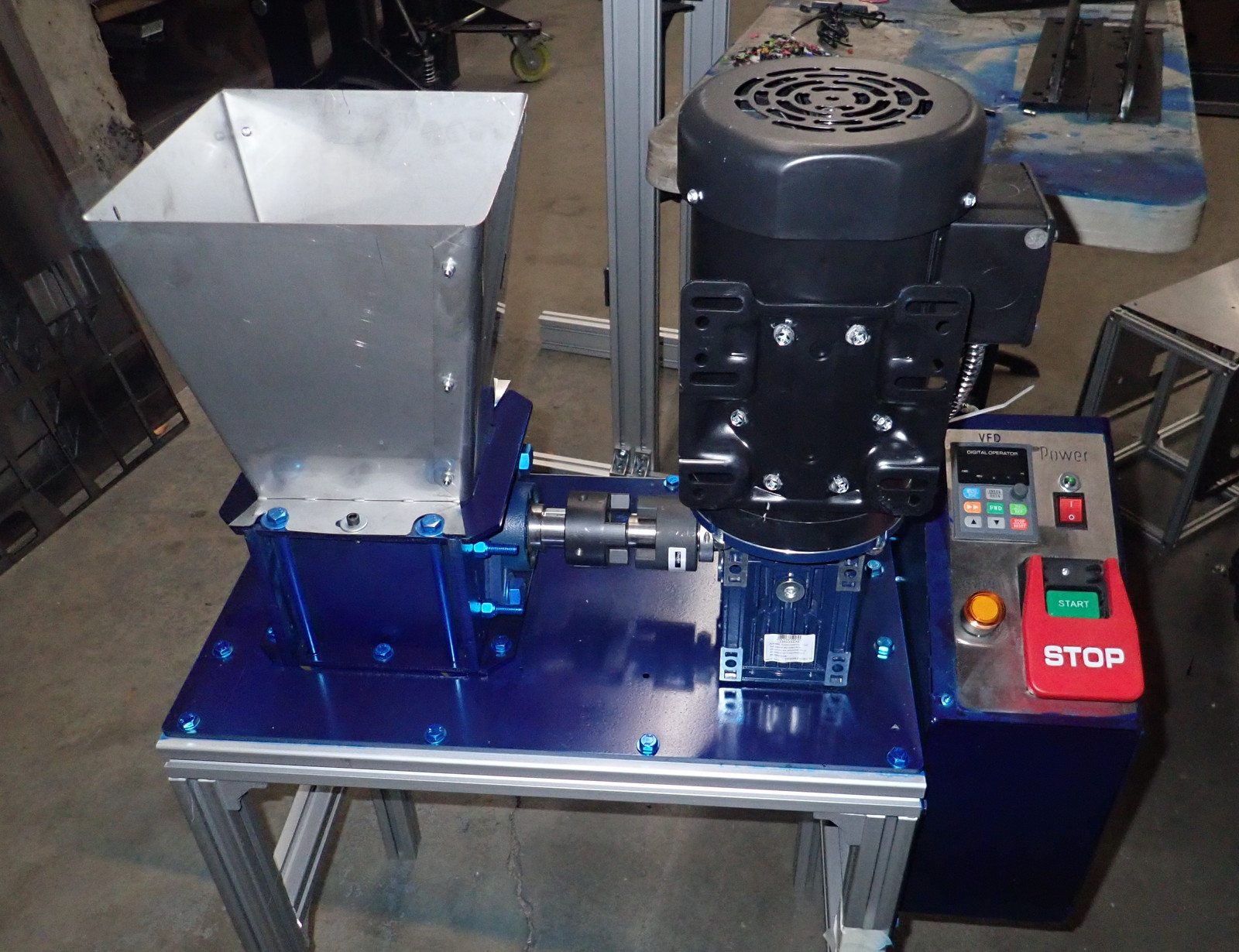

Outside, it’s a simple enough setup: Motor, gearbox, control panel with a very big stop button, and a coupler. If you’ve ever seen video of a large car shredder, hard drive shredder, or anything of the sort in operation, this is exactly the same, just smaller and R&D lab sized. Put a bin under it to catch the debris, which will be fairly well mixed coming out.

Heat and Pressure

Once the plastics are ground up, what then? One of their processing methods is just literally a big hot press - load it up with plastic, heat it, and squash it down (or not, as the case may be, depending on what you want out of it). This press has top and bottom heating elements that can be independently controlled as desired.

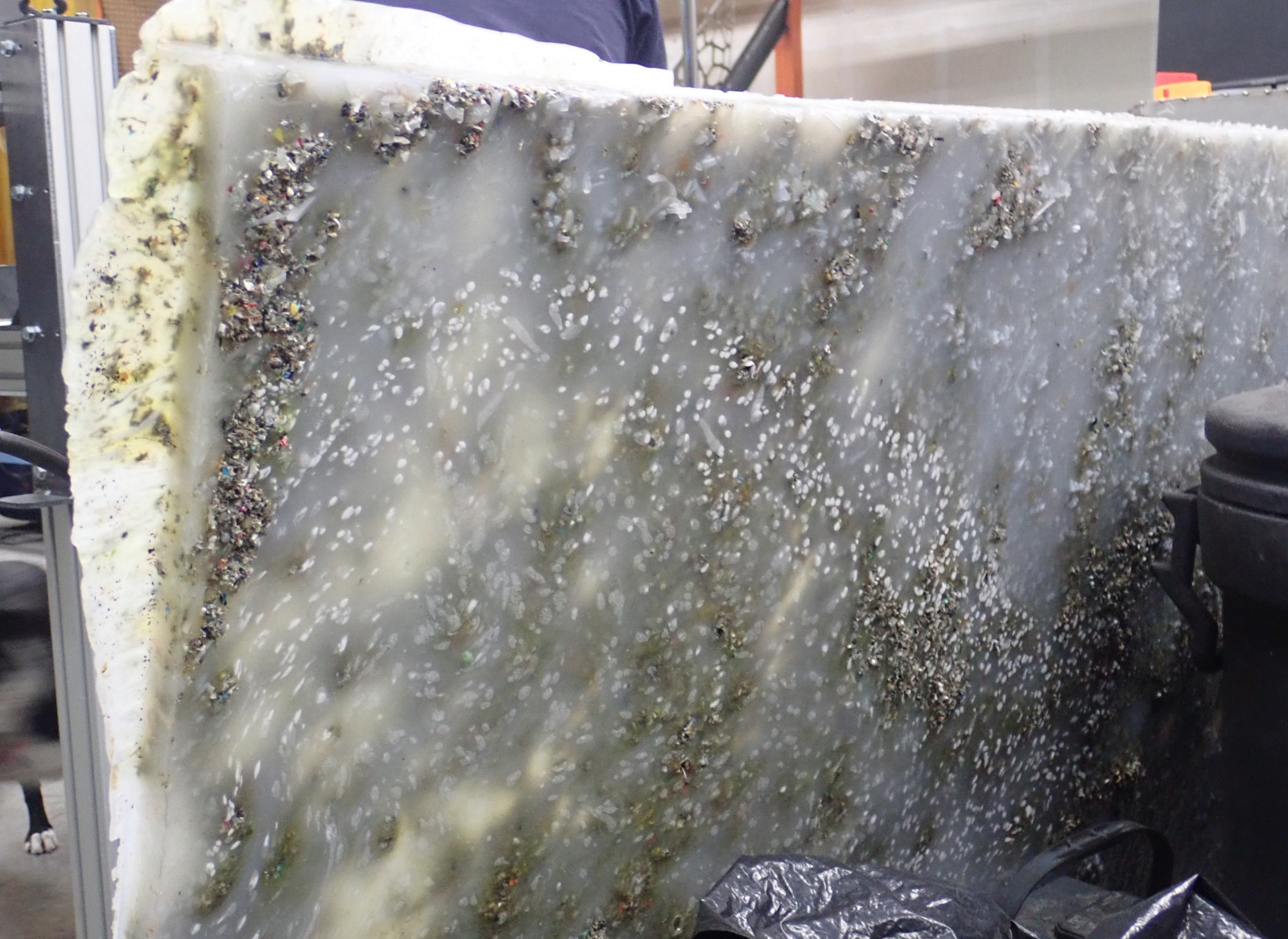

Apply heat, squeeze, and you end up with a sheet of plastic, showing the variety of materials that went into it. I was curious about the difference between thermosetting and thermoplastic plastics. Thermosetting plastics are the variety that gets hard when cured, and won’t re-soften - think epoxy that, once cured, won’t turn back into a liquid. Thermoplastics are the variety that get hard when cooled, but can re-soften when warmed up - think hot glue, where if you warm it up again, it turns back into a liquid. It turns out that in the normal mix of post-consumer plastic waste, there’s enough thermoplastic material to bond everything together. There’s plenty of thermosetting plastic, but it’s effectively an aggregate filler in the thermoplastic soup you get with heat.

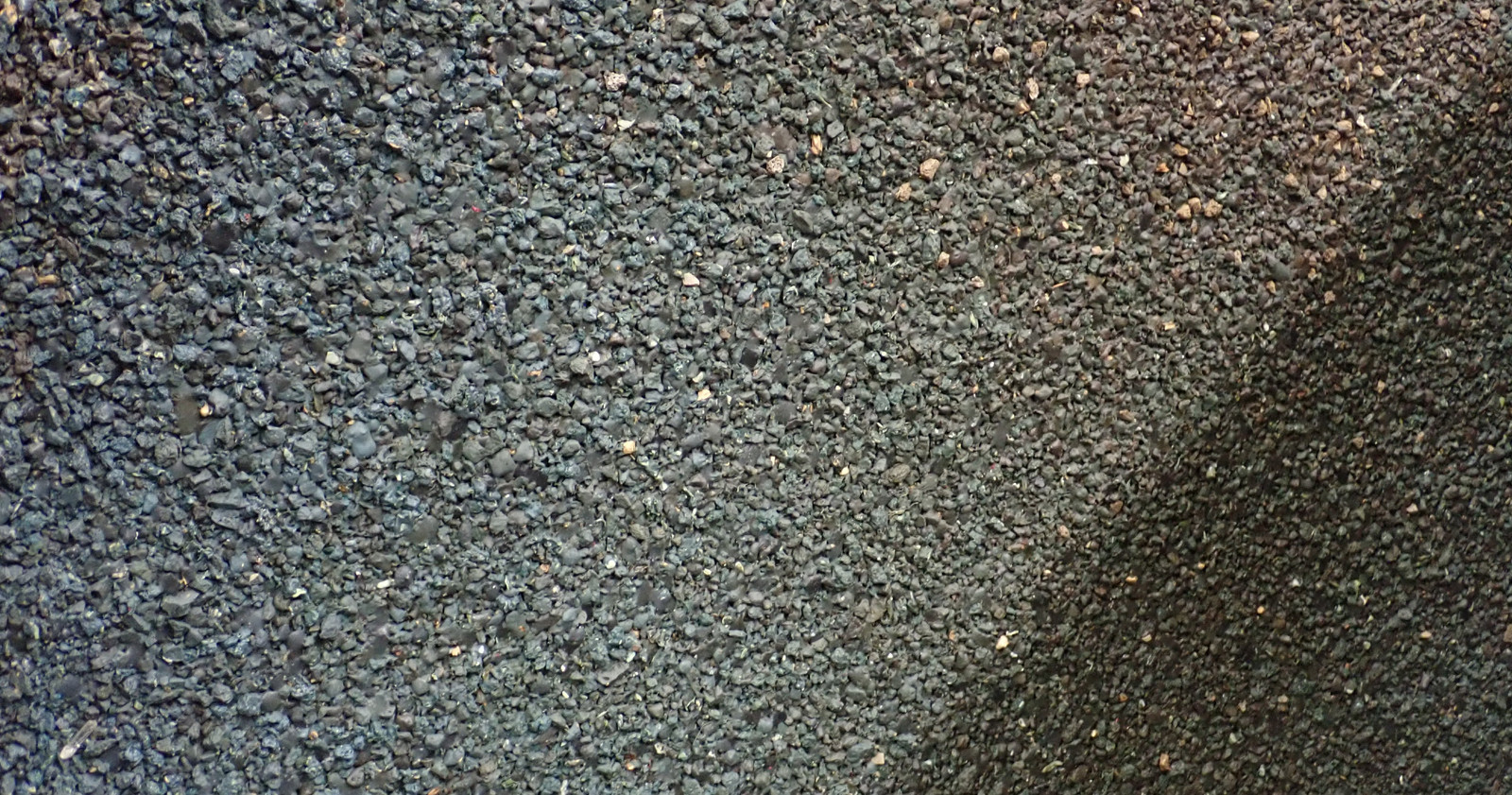

Heat only one side, and you get something that looks a lot like asphalt. It settles into a smooth layer and, at least in this particular attempt, heated enough to turn the surface a uniform black.

This is an example of some of the process of polishing and refining sample slabs of plastic into some coasters that can be handed out as samples. They’re polished up and labeled to show off the variety of results you can get out of the raw material.

Extruding: Even More Heat and Pressure!

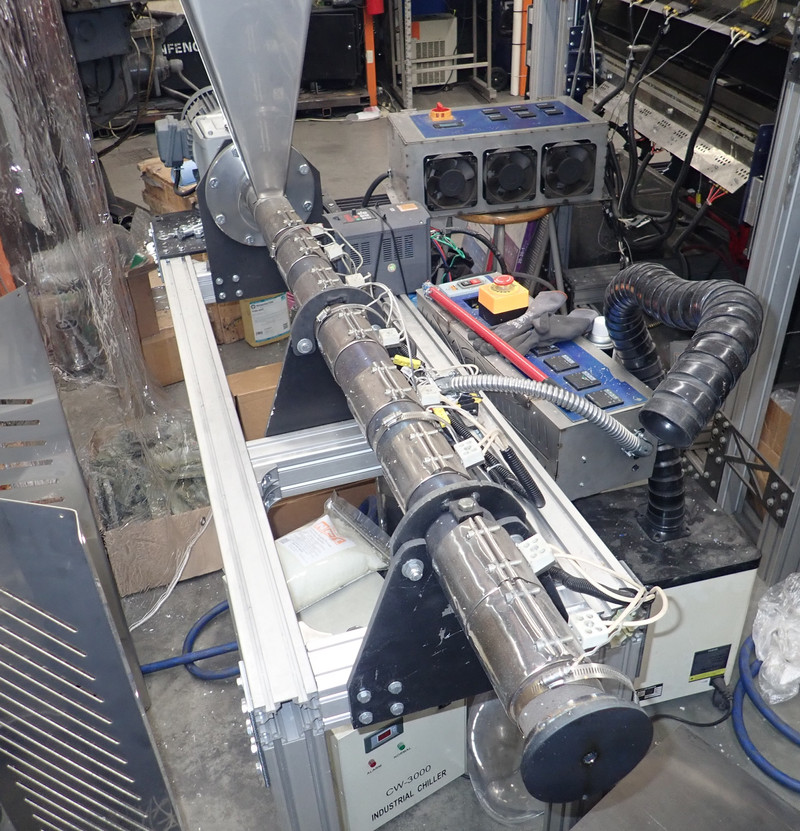

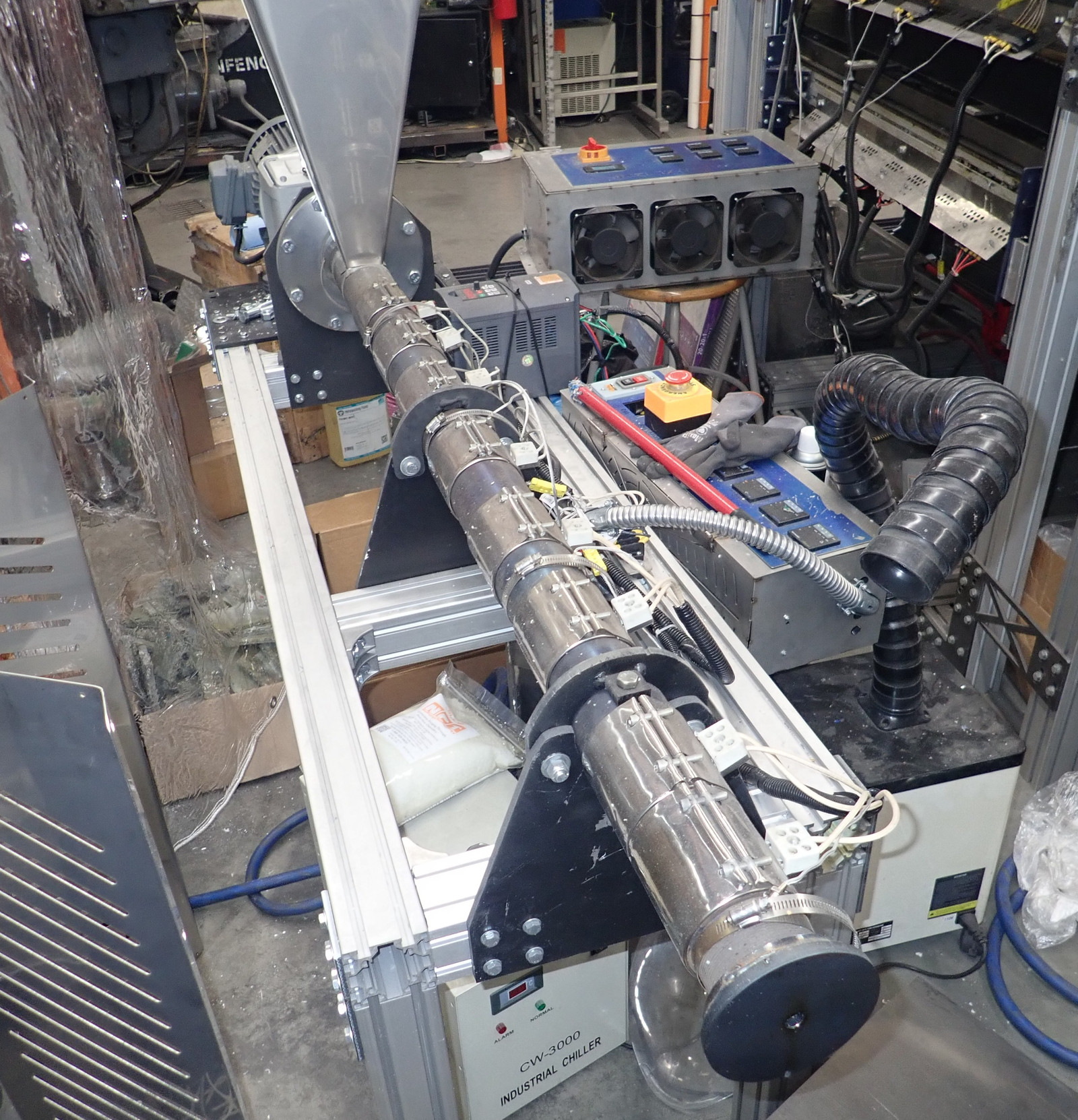

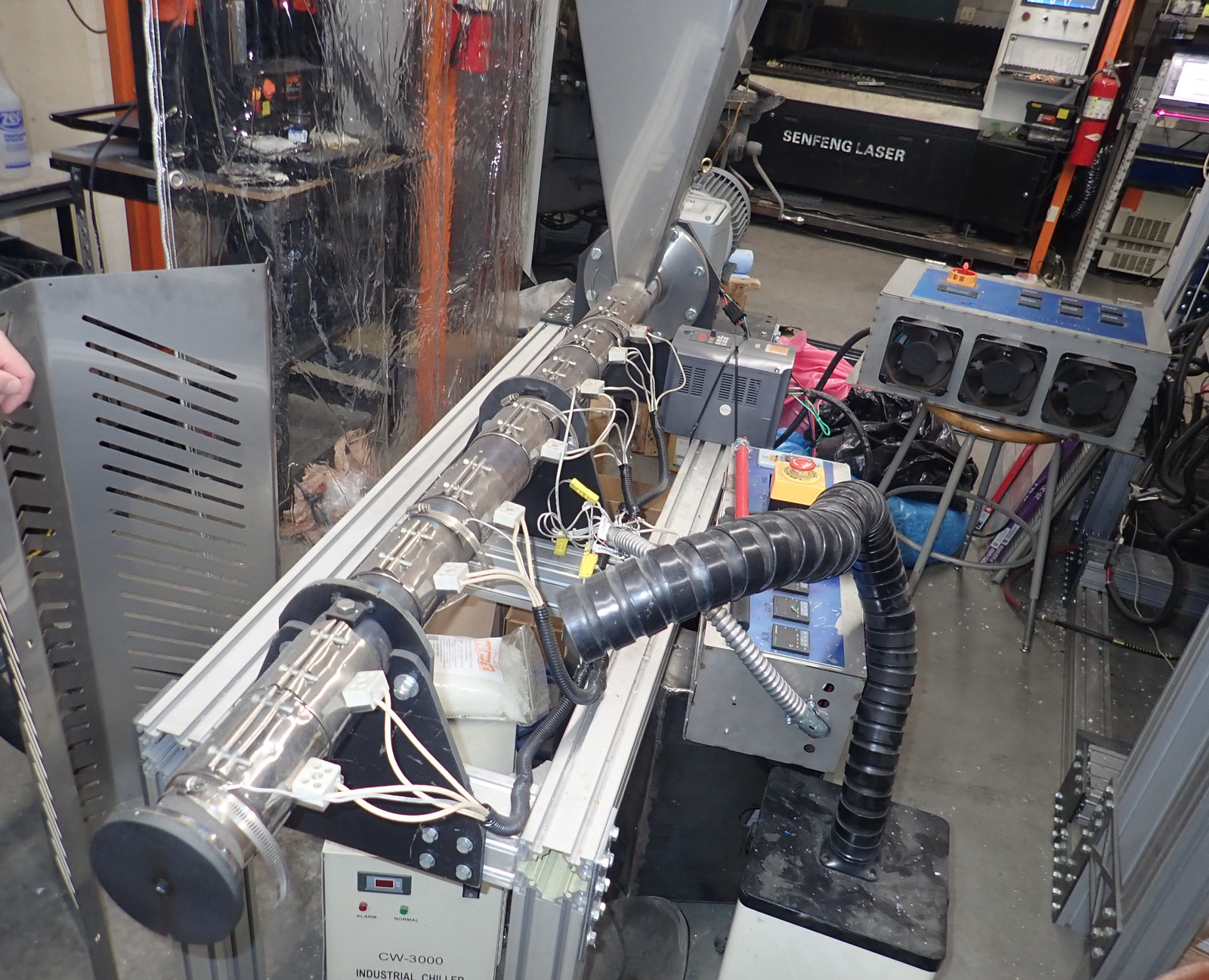

Another technique they’re playing with is extrusion - using a screw auger to really mix the plastics while they’re being heated, and then shoved at fairly high pressure into a mold. Here, the far end is a motor and gearbox, driving the auger. Chipped plastic is fed in the funnel and driven down the pipe. Wrapped around it, a range of heaters are clamped on to progressively heat the mix and allow it to flow together. If you’ve ever used a KitchenAid Pasta Extruder sort of gizmo, it’s like this - just with plastic.

It’s still very much a prototype - lots of exposed wiring, and a range of control boxes, plus a chiller that can be directed to help cool things down at the end. It looks like the sort of thing I’d put together in my office, really - but for R&D, being able to easily change things is a huge benefit.

Everything comes out that small hole in the end - and you can clamp a range of molds to it.

If you have a laser cutter, making molds isn’t hard at all! The molds they’ve been using are a three layer setup - one flat plate on the back, the actual shape in the center, and a front adapter with a hole that bolts up to the end of the machine. Build a mold, squeeze plastic in, cool it off, and pop it out!

Of course, you’re not limited to straight edges. One can build all sorts of fun little shapes and patterns!

Planter Boxes

Finally, they’re working on some planter boxes that support a range of custom “recycled plastic” sides. This is designed so the plant can be set at whatever depth is needed - no need to fill the whole thing with dirt when you’re just dealing with a plant that can handle a shallow amount. It’s a nice folded metal construction that wouldn’t look out of place in most restaurants or airports.

Then, you can drop in sides out of recycled plastic that provide for your neat art patterns! Recycled magic!

Does it Matter?

You can clearly get all sorts of unique patterns out of recycled plastic. But is this actually a good use for plastic? Will it make a dent in the streams of post-consumer plastic waste? My guess would be “probably not enough to matter.”

This is very interesting in the sense of “Yes, there are things you can do with post-consumer random plastic waste,” and it does generate some really novel art that I think needs to be displayed in quite a few places - if nothing else, to bring awareness to the scale of the problem.

I’m very glad there’s research in this space, and I look forward to what comes out of it. But it’s not changing the absolutely staggering amounts of “generally unusable plastics” coming out of our waste streams these days, and that’s a far bigger problem that needs to be addressed.

Nothing we’ve learned about plastics and their impact on the environment (humans are in the environment…) says they’re any good at all to have around. While I’ve got a way to deal with them (I still think most of them go to be burned in Utah at a cement kiln), most people don’t. I’d encourage you, in 2025, to try and find ways of reducing your amount of plastic waste - which, simply enough, means reducing the amount of plastic coming in.

And that? That, as you’ll rapidly learn, is damned near impossible in today’s world.

Comments

Comments are handled on my Discourse forum - you'll need to create an account there to post comments.If you've found this post useful, insightful, or informative, why not support me on Ko-fi? And if you'd like to be notified of new posts (I post every two weeks), you can follow my blog via email! Of course, if you like RSS, I support that too.